6 Emerging Trends and Technologies in Supply Chain Innovation

The global supply chain has experienced several disruptions since the pandemic hit. With rising costs across the board, increased consumer demand, and a shortage of labor and raw materials, there has been a crisis in supply chain management in the last few years.

Faced with such immense challenges, organizations are starting to realize the importance of supply chain optimization.

Fortunately, several technologies have also emerged that are promising to disrupt the global supply chain — but this time, in advantageous ways.

From the rise of artificial intelligence (AI) and the Internet of Things (IoT) to the use of drones and blockchain, these innovations are proving critical for the improvement and efficiency of supply chain processes. They have far-reaching implications that can uplift warehouse fulfillment, logistics, raw material procurement, and customer satisfaction.

Let’s take a look at some of the key technologies and trends from the last few years and the various ways they’re revolutionizing supply chains everywhere.

3-D Printing

It may not be that obvious, but 3-D printing technology holds the key to streamlining the supply chain. By leveraging 3-D printing technology, companies can significantly reduce costs associated with warehousing, shipping, and production.

At the same time, humble 3-D printers can tackle serious issues caused by tense geopolitical situations, pandemics, and extreme weather conditions.

How?

A 3-D printer can help companies shift the process of mass production from low-cost countries closer to home, doing away with logistics challenges associated with rising fuel costs, freight rates, and the delayed procurement of raw materials. It can thus reduce the carbon footprint of any organization in a huge way.

Several industries, such as aviation, medicine, and construction to name a few, are already beginning to see the benefits that 3-D printing can offer. They are using it to easily print parts, or create devices, that would otherwise take a long time to procure and build.

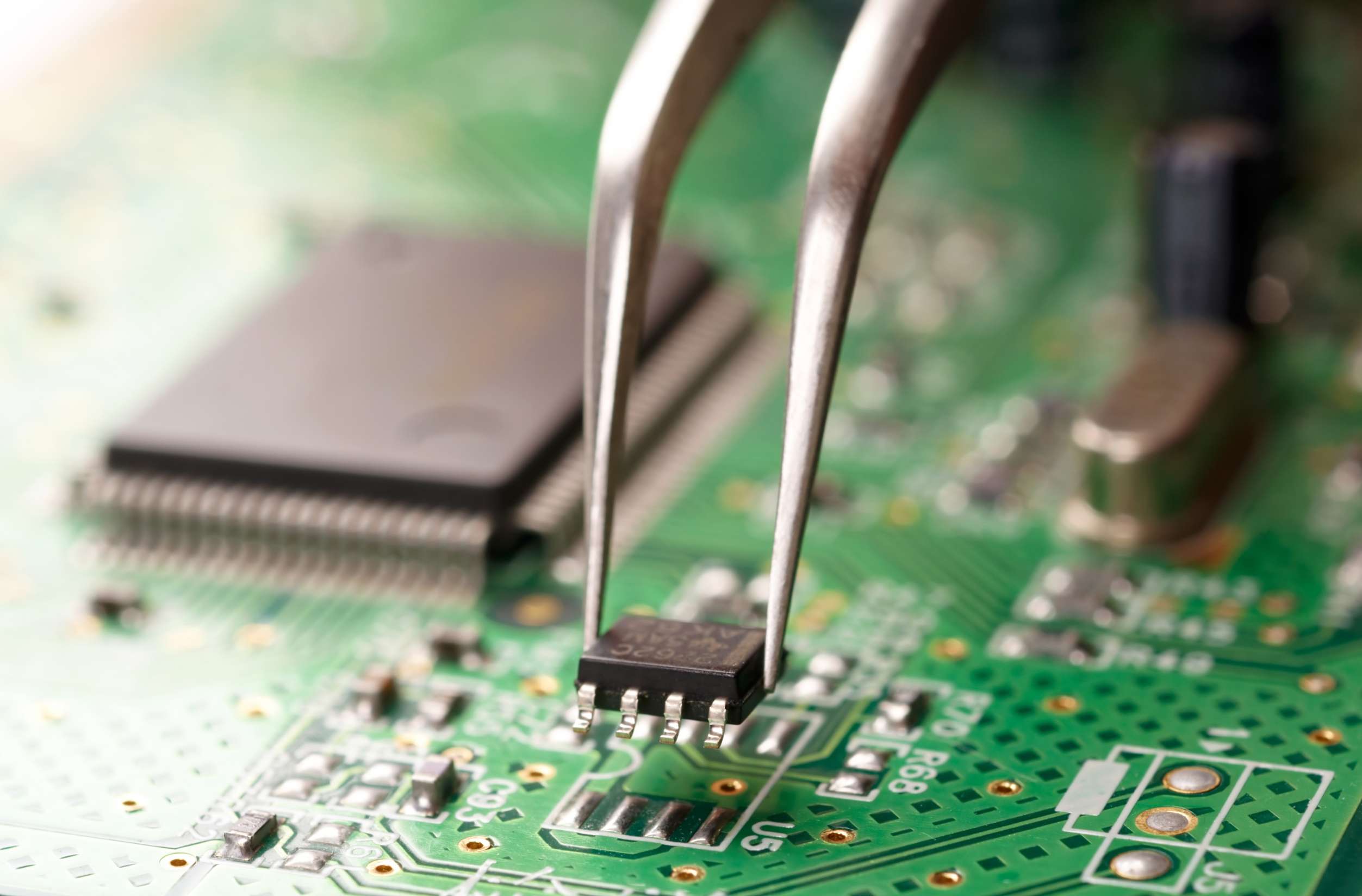

Robotics

Another major innovation in supply chains is the introduction of autonomous robots. It may seem like a passage from a science fiction novel, but robots are already helping increase production. They are often used to automate low-value tasks in warehouses, reducing the need for manual inventory checks and increasing the productivity of workers.

At the same time, autonomous robots can have a great impact on streamlining logistics due to their abilities that optimize picking, sorting, storing, and delivery times. Robotics can also increase customer satisfaction by doing away with human errors. In addition, they can enhance the safety of workers by taking over the most dangerous tasks.

For an example of how this looks in practice, consider Boston Dynamics. The robotics company has already created a robot that helps you load, unload and move cartons — a task that’s repetitive, time-consuming, and is known to cause major back problems among employees.

Drones

Similar to robotics, the rise of drones offers several benefits to the global supply chain, specifically in terms of logistics. Already tested by e-commerce giants like Amazon, drones have the potential to transform how goods and services are delivered, reducing human error and cost, and increasing efficiency and delivery times.

While the main advantage drones offer is the ability to move goods quickly, they can also be used to inspect inventories and track shipments since they can scan barcodes and take pictures of inventory.

Much like autonomous robots, drones can be used to inspect areas that are unsafe for humans. They can also be fitted with temperature and humidity sensors to ensure that goods are stored in the right conditions while preventing damage from external factors.

Blockchain

Blockchain technology has so far been commonly associated with cryptocurrency, but it is beginning to make its mark on supply chain management as well.

A blockchain is a distributed ledger that offers transparency and visibility in data and transactions. This allows it to be used to improve inventory management and streamline payments while offering higher security and lower costs.

When sourcing raw materials, for instance, a blockchain can hold information about the exact location where the materials were procured. It can also store information related to payments and receipts, ensuring farmers, loggers, or miners are adequately compensated.

Blockchains are beneficial for logistics too as they can hold information about every step in the process from production to distribution to delivery. A public blockchain can also allow customers to track the delivery of their product in real-time which is a much-needed innovation in last-mile deliveries.

While blockchain is still an underutilized technology, it has the potential to revolutionize all aspects of supply chain management.

The Internet of Things

There is an estimated 13 billion connected IoT devices around the globe, a number that’s expected to rise to 25.4 billion by 2030.

So, how are these figures related to supply chain management?

Internet-connected devices, such as temperature sensors, or GPS trackers, allow the collection of real-time data. This data could be comprised of goods that have been stored and transported, inventory levels, or shipment status. When this data is analyzed, it allows companies a way to continuously monitor the supply chain.

For suppliers of raw materials, IoT devices can help analyze data related to the quality of produce, or any potential hazards that may hamper production. Manufacturers can use the data to identify bottlenecks and reduce downtimes. Logistics operators can get real-time data on the location and status of all their assets while retailers benefit from increased picking accuracy and handling efficiency.

Whichever way you look at it, IoT has the capability to address a number of challenges faced by supply chain management today.

Conclusion

The global supply chain is in serious need of an update. In the face of several crises related to rising prices, labor shortages, and bottlenecks in delivery, there has been a lot of uncertainty on the proper course of action.

But with so many innovations and emerging technologies, we can safely say that the future of supply chain management looks hopeful.

Automation can help transform businesses that have huge inventories that need to be tracked and managed. Meanwhile, artificial intelligence can improve demand forecasting while facilitating lower costs and greater outputs. Technologies like these are encouraging more and more organizations to re-examine their processes and consider the benefits of adopting emerging innovations.