Manufacturing of Automotive Parts in China

1.1 History of automotive parts manufacturing in China

The history of automotive parts manufacturing in China dates back to the early 1950s, when the first domestic automaker, First Automotive Works (FAW), was established in Changchun. At that time, China's automotive industry was in its infancy, and the country relied heavily on imports to meet its automotive needs.

Over the next few decades, the Chinese government made significant investments in the automotive industry, with a focus on developing domestic manufacturing capabilities. In the 1980s, China began to open up its economy and encourage foreign investment, leading to the establishment of joint ventures between Chinese and foreign automakers. These joint ventures brought advanced technology and expertise to China and helped to build the foundation of the country's automotive industry.

By the 1990s, China's automotive industry had entered a period of rapid growth. The country's domestic automakers began to produce a wide range of vehicles, including passenger cars, commercial vehicles, and agricultural machinery. The government also established policies to promote the development of the industry, including tax incentives, subsidies, and regulations to protect domestic manufacturers.

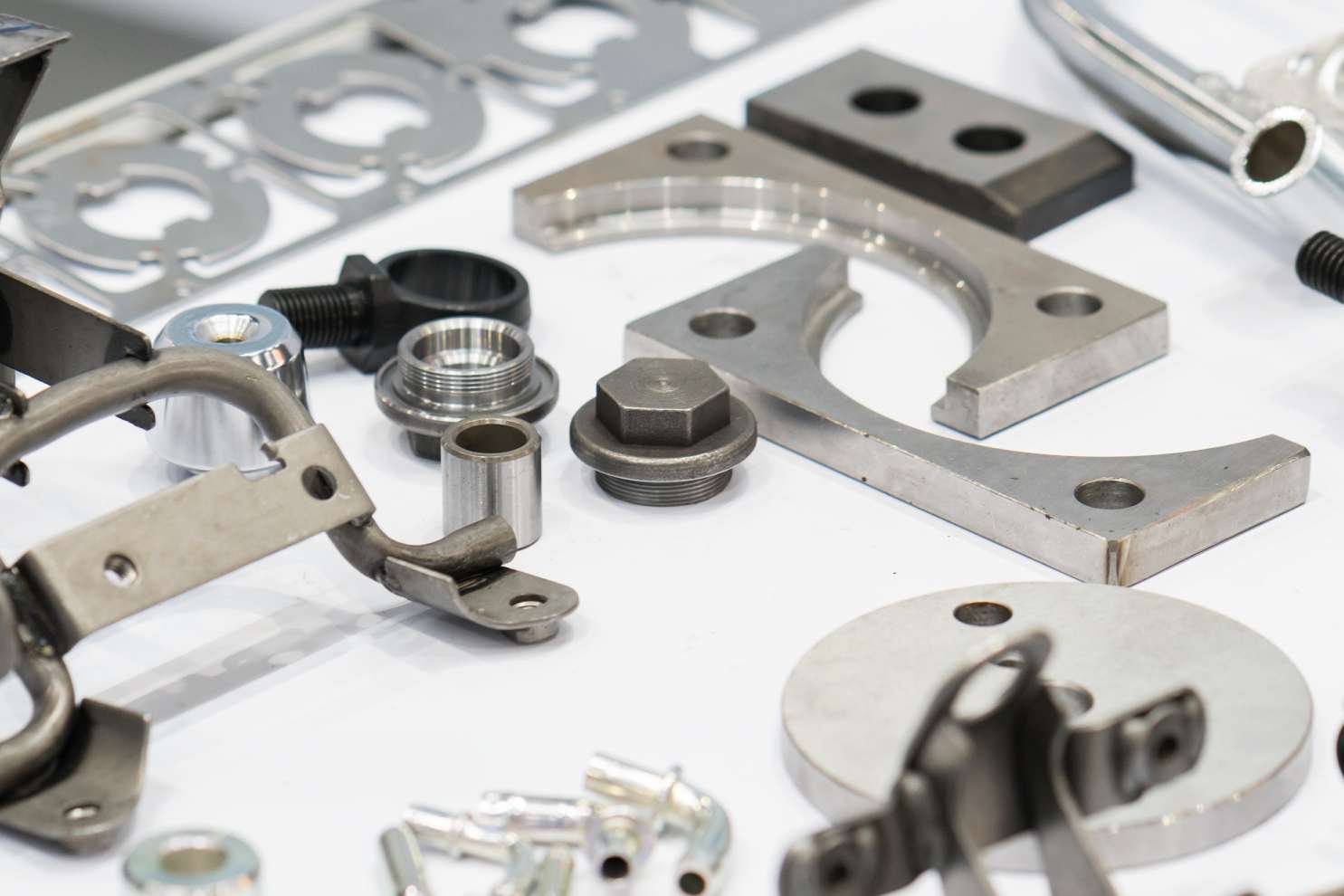

During this time, China's automotive parts manufacturing industry also grew rapidly. Chinese companies began to produce a wide range of parts and components, including engines, transmissions, suspension systems, electrical systems, and more. These parts were not only used by domestic automakers but also exported to other countries.

In the early 2000s, China became a major hub for automotive parts manufacturing. The country's vast labor force, low wages, and favorable government policies made it an attractive location for global automakers and suppliers to establish operations. As a result, many international companies began to set up manufacturing facilities in China, further driving the growth of the industry.

In recent years, China's automotive parts manufacturing industry has undergone significant changes, driven by the rise of electric and autonomous vehicles. Chinese companies have made significant investments in research and development in these areas, with a focus on developing new technologies and improving product quality. As a result, China has become a leader in the development of electric and autonomous vehicles and related components.

Despite its success, China's automotive parts manufacturing industry faces challenges, including increasing labor costs, a shortage of skilled workers, and environmental regulations. The country's government has implemented policies to address these challenges, including investment in automation and the promotion of environmental sustainability.

Looking to the future, China's automotive parts manufacturing industry is well-positioned for continued growth and success. The country's vast market, favorable business environment, and ongoing investments in innovation and technology make it an attractive location for global companies to establish operations. With ongoing improvements and advancements, China is set to remain a major player in the global automotive industry for years to come. Over the last three decades however, China’s economic growth has brought with it a significant improvement in the country’s collective manufacturing quality.

1.2 Current state of the automotive parts manufacturing industry in China

The automotive parts manufacturing industry in China is currently one of the largest in the world. The country produces a wide range of automotive parts, from basic components such as engines and transmissions to more advanced technologies like electric vehicle batteries and autonomous driving systems.

As per research, the number of cars on Chinese roads has increased by a whopping 187% – from around 104.9 million in 2011 to about 302 million in 2021. And this doesn’t even include motorbikes, scooters or trucks.

In recent years, the industry has undergone significant changes and faces both challenges and opportunities. Here are some of the key factors influencing the current state of the automotive parts manufacturing industry in China:

· Market Size

China is the world's largest automotive market, with a rapidly growing middle class and rising disposable income. As a result, demand for vehicles and automotive parts continues to increase, driving growth in the industry.

· Global Competitiveness

Chinese automotive parts manufacturers have become increasingly competitive globally, thanks to the country's low labor costs, a vast domestic market, and favorable government policies. Many international companies have also established operations in China to take advantage of these factors.

· Technological Advancements

The rise of electric and autonomous vehicles has presented both opportunities and challenges for the automotive parts manufacturing industry in China. The country has made significant investments in research and development in these areas, positioning itself as a leader in the development of new technologies.

· Environmental Regulations

China's government has implemented strict environmental regulations to address pollution and improve air quality. This has led to increased investment in green technologies and a shift towards electric vehicles, creating new opportunities and challenges for the automotive parts manufacturing industry.

· Skilled Labor Shortage

Despite a vast labor force, the automotive parts manufacturing industry in China is facing a shortage of skilled workers. This has led to increased investment in automation and robotics to improve efficiency and productivity.

· Supply Chain Disruptions

The COVID-19 pandemic has had a significant impact on the automotive parts manufacturing industry in China, disrupting global supply chains and causing shortages of critical components.

To address these challenges and take advantage of opportunities, the Chinese government has implemented a range of policies to support the automotive parts manufacturing industry. These include tax incentives, subsidies for new energy vehicles, and investment in research and development.

Chinese automotive parts manufacturers are also investing heavily in innovation and new technologies, such as electric vehicle batteries and autonomous driving systems. This has led to the emergence of new players in the industry and increased competition.

In addition to domestic demand, Chinese automotive parts manufacturers are also focused on global markets. Many companies are expanding their international operations and investing in research and development to develop new products and technologies.

Overall, the current state of the automotive parts manufacturing industry in China is one of growth and innovation. While challenges remain, such as the shortage of skilled workers and environmental regulations, the industry is well-positioned to continue its upward trajectory and remain a global leader in the years to come.

1.3 Analysis of China's advantages and challenges in automotive parts manufacturing

China's automotive parts manufacturing industry has grown rapidly over the past few decades, fueled by the country's large domestic market, favorable government policies, and low labor costs. However, the industry also faces significant challenges that could impact its long-term growth and competitiveness.

1.3.1 Advantages of China's Automotive Parts Manufacturing Industry:

· Large Domestic Market

China has the world's largest automotive market, with a rapidly growing middle class and rising disposable income. This provides a huge opportunity for Chinese automotive parts manufacturers to tap into the domestic market and expand their operations.

· Favorable Government Policies

The Chinese government has implemented a range of policies to support the automotive parts manufacturing industry, including tax incentives, subsidies for new energy vehicles, and investment in research and development. These policies have helped to attract foreign investment and support the growth of the industry.

· Low Labor Costs

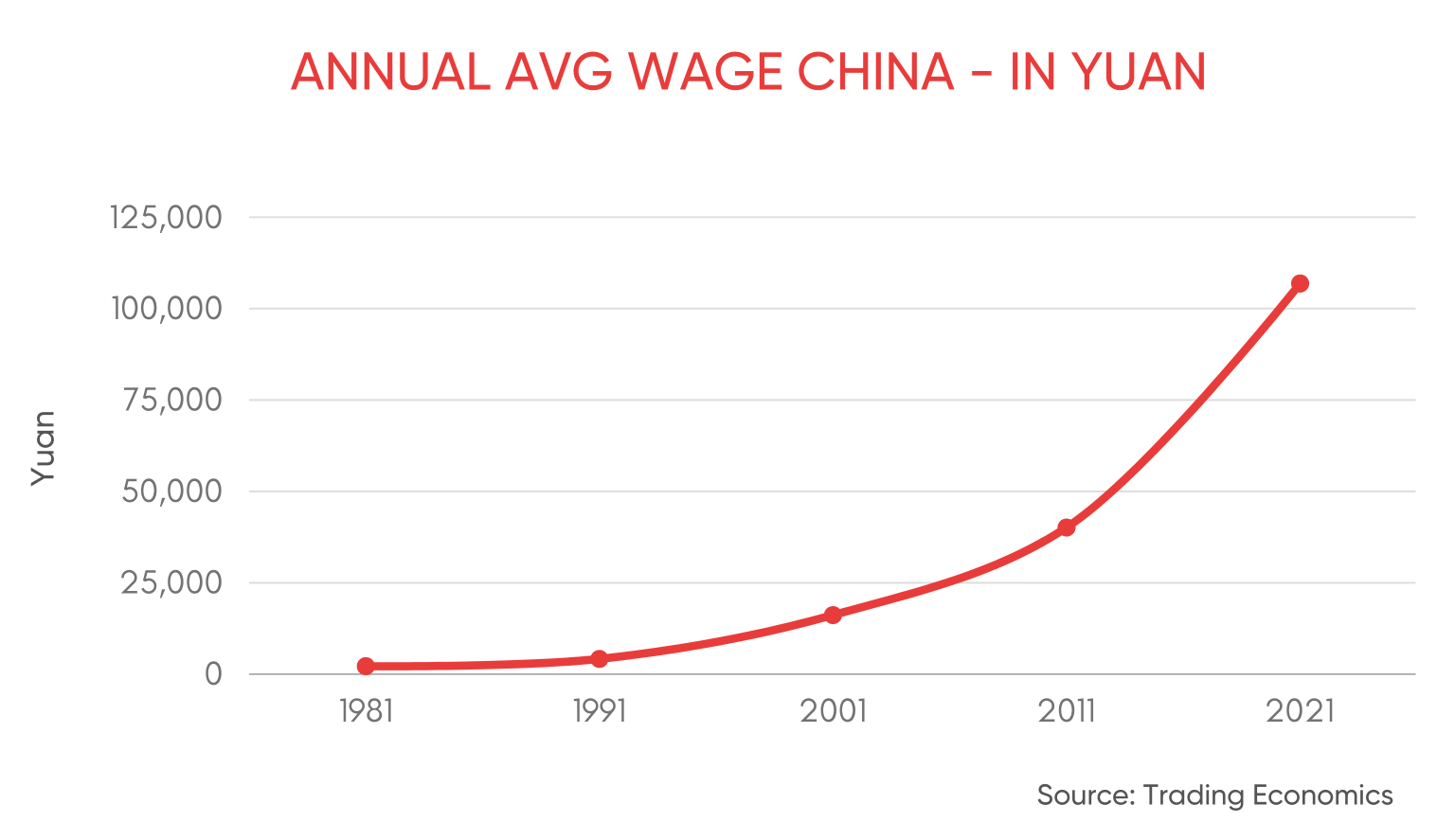

China's large labor force and low wages have made the country an attractive location for automotive parts manufacturing. This has allowed Chinese companies to offer competitive pricing and gain a foothold in global markets.

· Skilled Labor Force

Despite a shortage of skilled workers in some areas, China has a large pool of talented engineers and scientists who are capable of driving innovation and developing new technologies. This has helped to establish China as a leader in electric vehicle technology and other emerging areas.

1.3.2 Challenges Facing China's Automotive Parts Manufacturing Industry:

· Environmental Regulations

The Chinese government has implemented strict environmental regulations to address pollution and improve air quality. While these policies are necessary, they have also increased the cost of manufacturing and created challenges for companies operating in the industry.

· Quality Control

Chinese automotive parts manufacturers have faced criticism for quality control issues, which has led to concerns about product safety and reliability. This has impacted the reputation of Chinese manufacturers and made it difficult for them to compete with established international brands.

· Intellectual Property Rights

China has faced criticism for its weak protection of intellectual property rights, which has made it difficult for companies to protect their innovations and compete on a level playing field with international rivals.

· Supply Chain Disruptions

The COVID-19 pandemic has had a significant impact on the automotive parts manufacturing industry in China, disrupting global supply chains and causing shortages of critical components. This has highlighted the need for diversification and resilience in supply chains.

· Rising Labor Costs

While China's labor costs are still relatively low compared to developed countries, they have been rising steadily in recent years. This has led some companies to relocate their operations to other countries with lower labor costs.

To address these challenges, the Chinese government is implementing a range of policies to support the industry's growth and competitiveness. These include investment in research and development, support for emerging technologies, and efforts to improve quality control and protect intellectual property rights.